|

Bf 109G-10 Type 110

Cowling Conversion, 1/32 scale

Cutting Edge Modelworks

|

S u m m a r

y |

|

Catalogue Number and Description |

CEC32139 - Bf

109G-10 Type 110 Cowling Conversion |

| Price: |

USD$29.99 from Meteor

Productions website |

| Scale: |

1/32 |

|

Contents and Media: |

16 parts in

grey resin |

| Review

Type: |

FirstLook and

FirstBuild |

|

Advantages: |

Good shape

capturing the characteristics of this unique sub-variant; excellent

casting; clever engineering; very good fit; relatively simple

preparation with only two cuts per fuselage side required; utilises

Hasegawa G-14 kit with better spine and canopy cross-section shapes

(compared to G-10 kit). |

|

Disadvantages: |

Some extras

will be required |

|

Recommendation: |

Highly Recommended

to experienced, large-scale Luftwaffe modellers |

Reviewed by

Brett Green

HyperScale is proudly sponsored by Meteor

Productions

Until fairly recently it was commonly thought that there was a

variant of the Bf 109G-10 with the DB605AS engine.

This was a fair assumption based on examination of wartime photos. A

number of very late-war Bf 109G-10s were observed with the streamlined

"asymmetrical" cowl but without the characteristic lower chin bulges.

These aircraft also shared another characteristic - the crescent-shaped

fairing on the fuselage side below the port side of the canopy was

substituted with a simple, flat rectangular panel.

Recent research uncovered the true story. These aircraft were powered

by the DB605D engine like the rest of the Bf 109G-10 family. However,

they were the subject of an attempt at the Messerschmitt Erla production

facility to further streamline the front end of the bulging fighter.

The oil cooler was made wider and shallower, and the plumbing was

redesigned. This led to a new wider and shallower oil cooler housing,

and permitted the lines of the lower forward cowl to be smoothed,

eliminating the cheek bulges. The main cowl contours were modified too,

as were various panels. This, in turn, led to different shapes for the

gun troughs. A new, larger supercharger intake was installed. The

squared-off port-side fairing was another key identifying factor.

Luftwaffe researcher Jean-Claude Mermet has labelled this the "Type

110 cowl". This is not a Luftwaffe designation, but is a convenient way

to name the cowl in the absence of an official designation.

The vast majority, if not all, of the Bf 109G-10s with the Type 110

cowl had the tall tail, but they were equipped with every possible

combination of short/tall tailwheel strut and narrow/wide wheels and

upper wing bulges.

Cutting Edge has now released a Bf 109G-10 Type 110 Cowling

Conversion in 1/32 scale for Hasegawa's Bf 109G-14 kit.

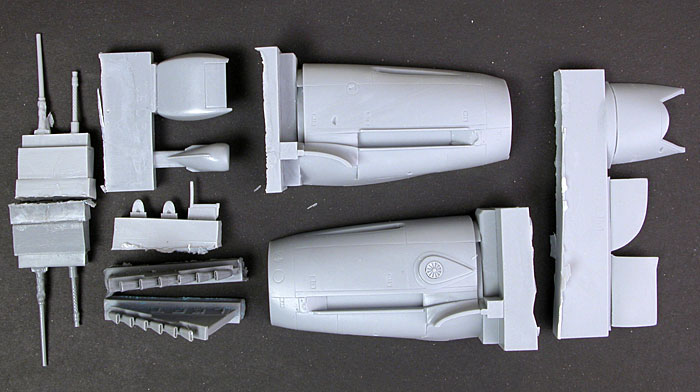

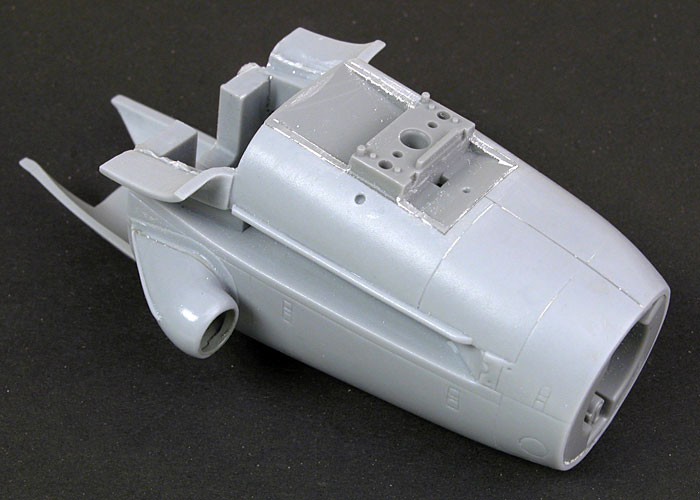

The set comprises 16 parts in Cutting Edge's customary grey resin.

The conversion includes new cowl halves for a hollow nose, top rear

"saddle", wide oil cooler housing, larger supercharger intake, both

fuselage fairings, scoops, machine gun barrels, exhausts and even a

starter crank.

The parts are perfectly cast and nicely detailed. All the obvious

major attributes are covered, including the re-shaped cowl and some more

subtle elements. One example is the redesigned gun troughs, which are

quite obviously asymmetrical due to the different shapes of each cowl

half. The contours of the new nose look good compared to photos and to

Mermet's drawings.

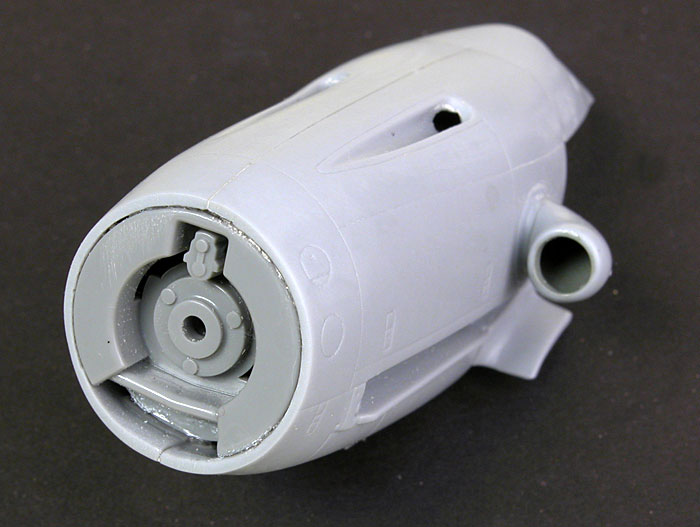

The cowl halves incorporate the firewall at the back of the parts. In

a clever piece of engineering, this firewall will ensure the correct

angle of attachment for the plastic fuselage halves, and for the top

saddle.

The new big supercharger intake is cast in one piece, and the

port-side cowl has turbine detail in place. The wide oil cooler has

locating pins - don't shave them off when cleaning up the part!

The instructions are good, including construction photos and detailed

text. You really should thoroughly familiarise yourself with the

instructions before you start cutting and gluing.

But why is this set designed for the G-14 kit and not the G-10?

Well, the G-10 kit has the crescent-shaped fairing moulded to the

fuselage. It would take a fair amount of work and a delicate touch to

remove the bulge and not damage the fuselage part.

In addition, Hasegawa represented the basic fuselage and cross

sections very nicely in the G-14 kit, but when they produced the G-10

they introduced an annoying error. The rear fuselage spine Hasegawa's

1/32 scale Bf 109G-10 kit has been flattened off. This is quite

noticeable and not at all accurate. Because this area coincides with the

Erla canopy, this part is also the wrong cross section.

The downside is that the G-14 kit comes with the earlier propeller

blades, and only with the small wheel bulges/narrow wheels and the short

tail wheel strut. The "Type 110" Bf 109G-10s could be fitted with big or

small wheels; and either long or short tailwheel struts, so depending on

the aircraft you are depicting the wheels and bulges might not be an

issue. If they are an issue, Cutting Edge already offers a long

tailwheel set with white metal strut. MDC has a very nice long tailwheel

set too, plus the G-10 wide wheels in 1/32 scale. It is only a matter of

time until we get a wide bulge in resin from someone!

The first task is to remove the parts from their casting blocks.

When you are removing the big cowl halves, make sure you cut as close

as possible to the casting block in order to retain the firewall area.

This is an important alignment aid for the kit fuselage halves and the

resin top rear cowl. The opening for the oil cooler mount is flashed

over. I scored around the outline with a scriber then cut most of this

resin away with side cutters before tidying up with a sanding stick and

hobby knife. Preparing each cowl half took around ten minutes. The

openings for the cowl guns is also flashed over. This was opened with

side cutters and cleaned up with a sharp hobby blade.

I recommend that the resin "sprue" that holds the top rear cowl and

the two fairings is cut in two before the parts are separated. I cut

this sprue with a razor saw between the cowl and the fairing. The

fairing parts are very thin and delicate. Overzealous sawing of the cowl

might damage the fairing if they are both attached to the sprue at the

time.

Some of the blocks look quite imposing but most of the parts are

quickly removed. I took my time, used the right tools (razor saw for

straight cuts, hobby knife for cleaning up, sanding stick for finishing

off), cut close to the blocks and got a good result without too much

fuss.

Assembly Sequence

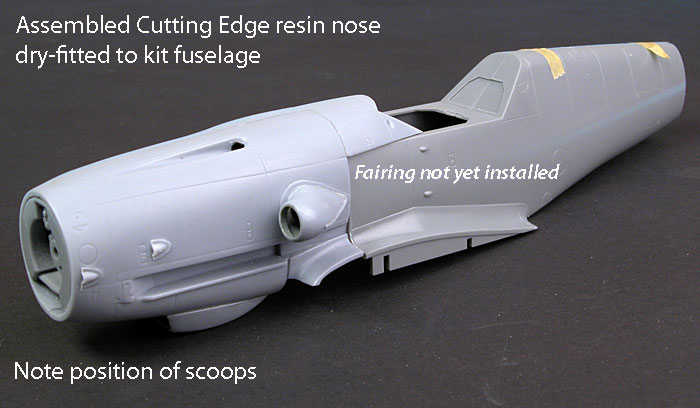

I almost followed the instructions. After all the parts were

prepared, this is the assembly sequence that I decided on:

-

The kit parts were prepared. First I

cut off the nose along the vertical cowl panel line with a razor

saw. I left around 0.5mm extra material in place in case I will need

it during final assembly. Next, the top "saddle" part was removed.

-

The resin cowl halves were test

fitted and glued. Test fitting showed that these big resin parts

were quite flexible, so first I superglued the rear firewall section

and the top-rear join. When this had dried, I aligned the join at

the top of the cowl and ran a bead of surperglue along the join line

on the inside of the cowl. Don't do this on the outside or

you'll have a horrible mess to clean up! When the top join was set,

I held the bottom cowl join and repeated the gluing step. The fit

was excellent. A light once-over with a sanding stick eliminated any

tiny ridges. At some stage I will add a hinge line to the top of the

cowl - probably a very thin piece of stretched sprue

-

I installed kit part A22, the

horseshoe tank face, into the front of the cowl. I originally

thought I might glue tabs inside the cowl halves to establish a firm

join, but the fit was so good I did not need to. I pushed the

plastic part into place, fiddled a bit to make sure everything was

straight, then ran a bead of superglue around the part from the

inside of the cowl. With the hole for the oil cooler still open,

there is plenty of room to manoeuvre with a small tube of super

glue.

-

Next, I installed kit part G5, the

oil cooler mounting plate. Test fitting showed that the part would

stick out 1-2mm at the rear, so I used a sanding stick and hobby

knife to make the opening slightly longer at the front. I ran a bead

of super glue around the edges of the kit part then pushed it into

place for a gap-free fit.

-

I glued the saddle-shaped top rear

cowl part to the back of the nose assembly. I figured this would

ensure perfect alignment at the top rear cowl join line, and will

also provide an additional point of reference when the resin nose is

glued to the plastic kit fuselage.

-

After this, you can paint the kit oil

cooler faces (parts M5 and M6) and glue them in place; add the

supercharger intake, the oil cooler housing and intake scoops. There

are only two scoops supplied but you'll need four. Just slice two

off the discarded kit nose.

That is as far as I have gotten, but on

my return from the USA I will be building the remainder of the kit and

mating the resin nose to the plastic. Once the nose and the fuselage are

together, then I will add the fairings.

The Messerschmitt Bf 109 is without doubt my favourite aircraft and

the Type 110 cowl variant has been one of my most-wanted conversions in

either 1/48 or 1/32 scale.

To my eye, this version is the ultimate expression of grace and grunt

in the Bf 109. The elimination of the chin bulges and the streamlining

of the nose returned the smooth lines lost since the Bf 109G-4, yet the

muscular bulk of the DB605D is also obvious. I am therefore delighted to

see Cutting Edge's 1/32 scale Bf 109G-10 Type 110 Cowl Conversion.

I am impressed with the unique shapes, the clever engineering and the

excellent fit of Cutting Edge's resin parts.

I am also quite pleased with the decision to base the conversion of

Hasegawa's 1/32 scale Bf 109G-14 kit, even though some work to the prop

blades will be required and, depending on which aircraft you are

building, new wheels/bulges might also be necessary.

The Cutting Edge 1/32 scale Bf 109G-10 Type 110 Cowl Conversion will

be within the abilities of most modellers with resin experience, and

will result in a very different look for your Hasegawa Bf 109G.

Highly Recommended.

Thanks to Meteor Productions for the review samples.

Cutting Edge Modelworks products are available from

Meteor Productions Website

Text and Images Copyright © 2004 by

Brett Green

Page Created 30 July, 2004

Last updated 30 July, 2004

Back to HyperScale

Main Page

Back to Reviews Page

|

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search