|

U-2R / TR-1 Wing Correction

Cutting Edge Modelworks

Previewed by David W. Aungst

HyperScale is proudly sponsored by Meteor

Productions

Cutting Edge is about to release three new update sets for the

late generation U-2. I made the masters for all three sets. I'll apologize

here up front for my enthusiasm about them. I am overjoyed with the way

the resin pieces came out and look forward to using them in my current

U-2S model. I'll try to keep the text objective here and let the pictures

of the pieces do the talking, but my enthusiasm will likely bubble

through.

I am only going to show the pieces at they come out of the set in this

review. Expect to see a built-up U-2S in the coming months on HyperScale

using all these sets.

This review is on the Wing Correction Set (CEC48441).

An Update

Set or a Correction Set?

|

This set is more than a simple update to the wing. It also corrects

some minor size issues with the wing control surfaces.

Before getting started with the creation of the flaps, I wanted to

determine the true details of the U-2 wing. Pictures I looked at showed

the details between that the flaps and ailerons were not captured quite

right on the kit. Further, the ailerons just seemed too big (long in span)

compared to the flaps. I decided the only way to be sure of all this was

to make a detailed comparison of the kit wing to known sizes on the real

aircraft.

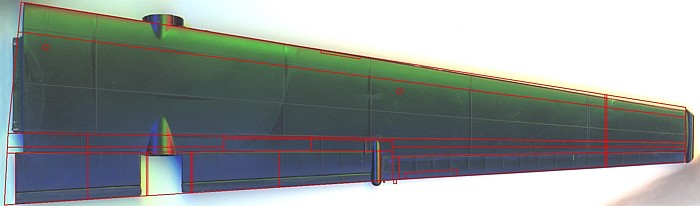

On the rear cover of the Minigraph #28 book on the U-2R, there is an

engineer's drawing of the U-2R wing with all the design measurements

included. This seemed a good place to start for the camparison. I scanned

an image of the kit wing into my PC. Then, I scanned an image of this

diagram into my PC. Through a little foreplanning and some electronic

slight-of-hand, I got the images scaled to the same size and rotated to

nearly the same angle, then I super-imposed the diagram over the kit wing.

The following image was the result.

Wing Detail Comparison — Click the

Picture to View a Larger Image |

Several points are noted with close inspection of this image (click the

image to see the working copy I used for my actual analysis). Starting

from the wing root and moving outward:

-

The super pods are off by 1/8th

inch (a scale six inches). They are a little too close to the fuselage.

-

The span of the outboard wing flaps is not

long enough. This makes the break between the flaps and ailerons move

inboard 3/16th inch (a scale nine

inches).

-

The small non-moving section of the wing

between the flap and aileron is not represented in the kit at all. This

is the section where the fuel dump pipe is found. Acording to the

engineer's diagram, this section is six inches wide. This missing

section plus the shortened outboard flaps account for why I thought the

ailerons looked to long in span -- they are.

-

The aileron trim tab should not be as large

as the kit has it molded. It should be three feet, nine inches in span,

offset six inches from the inboard end of the aileron. The kit molds it

as five scale feet, flush with the inboard end of the aileron.

-

To make the aircraft easier to handle on

the ground, the outboard 70 inches of each wingtip can be folded. The

scribed lines for the fold on the kit are a scale foot too far inboard,

increasing the size of the folding wingtip.

-

Lastly, the wing cord at the tip is not

wide enough. This seems due to the leading edge of the kit having a very

slightly larger angle of sweep then it should while the trailing edge is

represented pretty close to where it belongs.

Before giving Italeri too much grief over these wing issues,

remember that this kit was created in the early 1980s when practically

everything about the U-2R was classified. The diagram I am using for my

comparison here was not published until many years after the kit was

released. That the details are as close as they are is actually a credit

to Italeri.

I wanted to create a wing update set to fix most all the inaccuracies

noted above -- all but one. The moving of the super pods six scale inches

(1/8th inch) outboard was something I

figured most modelers would not care about. If I had created the parts

with the super pods moved outboard, every modeler using this set would get

caught having to make the fix to where the super pod fairings are molded

onto the kit wing pieces. Hence, I chose to fix everthing else, but left

the super pod locations in place.

Industrious modelers that want absolute accuracy can easilly make some

small adjustments to the kit and resin pieces to move the super pods if

they like.

Creating the wing flaps was not difficult. They are simple flat slabs

with no curves to worry about. I cut 0.015" sheet styrene to the proper

sizes, then assembled them with liquid cement. I filled the seams after

assembly using super glue. I eyeballed the angle for how far to drop the

flaps, then added tabs to the leading edges that would insert into the

wings and hold the flaps at the proper angle.

I created the ailerons by starting with the kit pieces that I had cut

off my set of U-2 wings. I sanded these smooth and cut them to the correct

length. I added some styrene strip to the leading side of the pieces to

increase the aileron cord to the proper size. Then, I scribed in the trim

tabs and added the trim tab actuators to the lower sides.

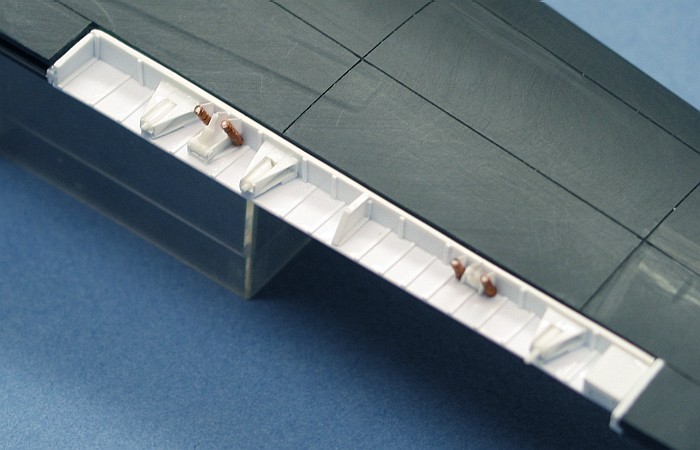

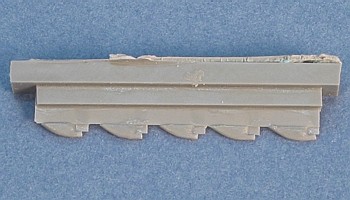

I created the spoiler wells using a similar approach to what I did for

the wing flaps. The wells are basically long skinny boxes that I built

from sheet and strip strene. Once I had the sizes worked out, I added the

inide details like the various actuators. The most involving parts to

create were the tension springs for the spoiler actuators. They are thin

copper wire stolen from a broken electric motor, wrapped around a piece of

styrene round stock, then carefully measured and cut to length. All the

spoiler actuators have small 0.005" sheet styrene mold relief walls added

behind them so the pieces would be cast-able as single pieces.

Completed Wing Spoiler Well |

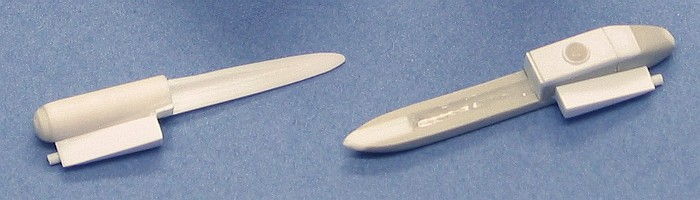

The measurements provided on the engineer's drawing of the U-2 wing

provided me with the exact sizes for the GPS and System 20 fairings. I

created the GPS fairing with some Plastruct 3/16th

inch square stock, filling the center hole and filing the proper shape

into the ends. The System 20 fairing is Evergreen 3/16th

inch tube stock which I again filled the center hole and filed the proper

shape into the ends. Both fairings are integrally created with a small

(six scale inch) section of the wing that does not move. On this

non-moving wing section is found the fuel dump pipe for each wing.

GPS and System 20 Fairings |

The final parts in the set are the scoops. Five cooling scoops are

found on the outboard sides of the two super pods (three on the left pod

and two on the right pod). Two other scoops of slightly different shape

are found, one under each wing. These are the fuel tank pressurization

scoops for pressurizing the wing fuel tanks in the event of needing to do

an emergency fuel dump.

The

Correction Set Described

|

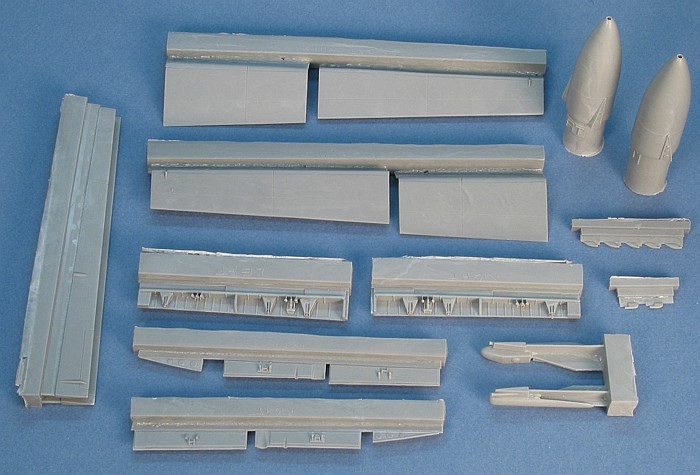

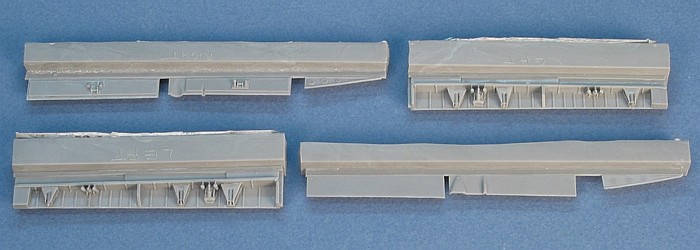

The set is large and made up of twelve pieces, molded in the medium

gray resin that we have come to expect from Cutting Edge. There

were no molding imperfections in the test pieces sent to me.

The Full Correction Set |

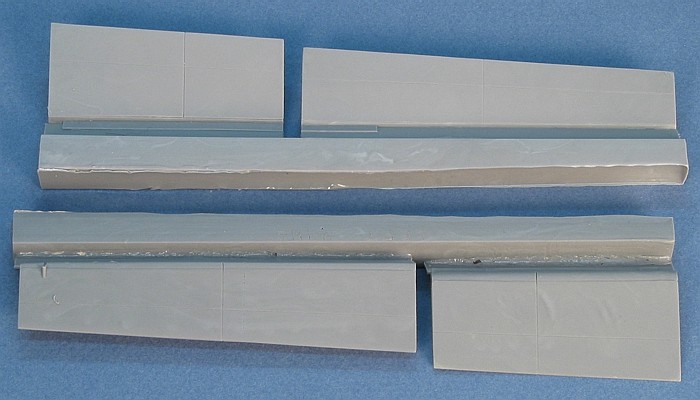

The flaps are broken down into inboard and outboard sections. Recessed

lines in the flap panels show the further separation of each panel into

two interconnected unit. The flaps are designed with tabs that extend into

the assembled wing halves and ensure the angle at which the flaps are

hanging.

Wing Flaps |

Outboard of the flaps on each wing is an antenna fairing. The left side

is the GPS antenna. The right side is the System 20 antenna. The pieces

have the whole fairing represented, including the extended portions found

on the underside of the wings. Itegral with the antenna fairings is the

small non-moving portion of the wing trailing edge where the fuel dump

masts are located.

GPS and System 20 Antenna Fairings |

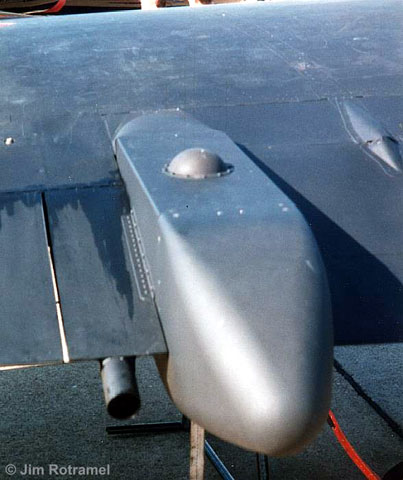

Super Pod Tail Cones |

The super pod tail cones are updated to include the aerodynamic

fairings that close the gaps between the pods and the wing flaps. They

also have the vent hole foud in their tips.

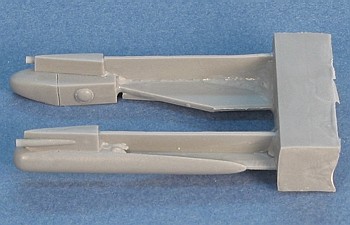

Next is the ailerons. They are molded with a portion of the aileron

actuator at their center. The trim tabs are scribed in the correct

location with their actuator fairing on the underside. The scribed line

near to the outboard end is the break point for the folding wingtip.

Ailerons |

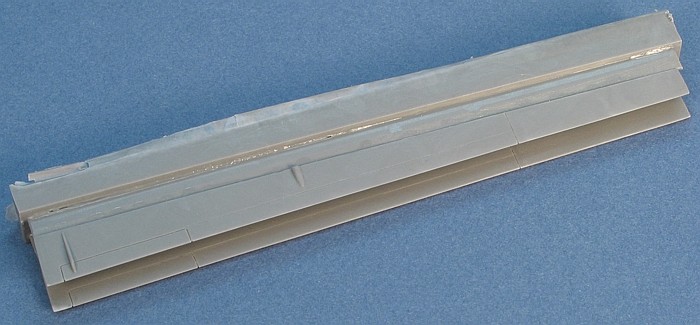

The last large pieces in the set are the wing spoilers. This is one of

those funky details that I wanted to include in the set, even though it is

extremely rare to see the spoilers raised on the ground. Instructions in

the set include details for using the set without raising the spoilers.

The two small triangular pieces next to the spoiler panels are facing

plates to detail the fuselage side that is exposed when the wing flaps are

lowered.

Spoiler Panels and Wells |

Rounding out the set is a series of tiny intake scoops. The group with

five scoops (the thinner looking ones) are for the outboard sides of the

super pods. Three scoops go on the left super pod; two go on the right

super pod. The group with only two scoops are the fuel tank pressurization

scoops. These mount under the wing, close to where the pogo legs are

attached. Note that the locations of the pogo legs in the kit are

incorrect and must be moved outboard almost three scale feet. The update

set instructions tell how far to move them.

Fuel Tank Pressurization Scoops |

Super Pod Scoops |

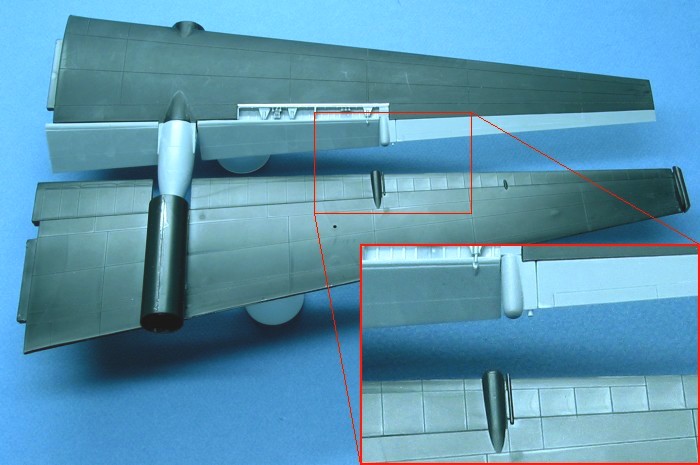

The following picture highlights the correction aspect of this set.

Besides the wing spoilers being enlarged and detailed, the break between

the wing flaps and ailerons was moved out. This is most evident by the

position of the System 20 fairing. Note also the non-moving portion of the

wing just outboard of the System 20 fairing and the corrected size of the

aileron trim tab.

Wing Correction Details |

I wrote this review to show a little of what goes into the making of a

set of masters for a resin kit update. And, of course, I wrote this to

show off the new set. The castings caught every detail of my original

masters with great clarity. As the designer of the masters, I do not think

it is my place to recommend this set or not. I will let the pictures in

this posting speak for themselves and leave any recommendations to a more

objective reviewer.

As many people have noted, the list of statistics at the end of each of

my project postings makes me a true "bean counter". This posting would not

be complete without listing my time spent on the project. For the record,

on all three U-2R/S update sets collectively, I spent 86.2 hours (5.9 on

research, 80.3 on contruction). Very few models in my built collection

have reached this high a number of working hours. Wanting to build more

than just one U-2R/S (eventually), the time spent here will save me time

in having to scratch-build all these items for each U-2 model that I

build.

(Newest to Oldest)

-

U-2R/S Walk Around by David W Aungst

On-Line

HyperScale Reference, 2003

-

U-2: The Second Generation by Chris

Pocock

World Airpower Journal, Volume 28, AirTime Publishing, 1997

-

Dragon Lady by Ted Carlson /

Toyokazu Matsuzaki

Koku-Fan Magazine, Volume 1996-04, Bunrin-Do Company, Limited, 1996

-

Recce Tech by Paul F Crickmore

Osprey Color Series, Osprey Aerospace Publishing, 1989

-

U-2 Spyplane in Action by Larry

Davis

, Squadron In Action #86, Squadron Publishing, 1988/2002

-

Lockheed U-2R/TR-1 by Jay Miller

AeroFax MiniGraph #28, AeroFax, Inc., 1988

-

Lockheed U-2 by Jay Miller

AeroFax AeroGraph #3, AeroFax, Inc., 1983

Cutting Edge Modelworks products are

available online from Meteor Productions

website

Images and Information Copyright © 2003

David W. Aungst

This Page Created on 21 April, 2003

Last updated

14 August, 2003

Back to

HyperScale Main Page

Back to

Reviews Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search