|

U-2R / TR-1 Fuselage Update

|

|

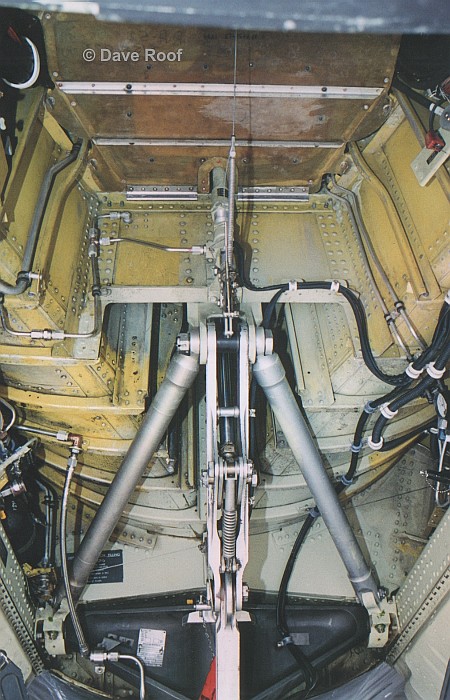

Actual U-2R/S Wheel Bay |

Cutting Edge Modelworks

S u m m a r y

|

| Catalogue Number,

Description and Price: |

CEC48442 U-2R/S/TR-1 Forward

wheel well bay, landing gear, and seamless air intakes |

| Scale: |

1/48 |

| Contents and Media: |

TBA |

| Price: |

USD$19.99

available online from Meteor

Productions website |

| Review Type: |

Preview and Detailed Look |

Previewed by David W. Aungst

HyperScale is proudly sponsored by Meteor

Productions

Cutting Edge is about to release three new update sets for the

late generation U-2. I made the masters for all three sets. I'll

appologize here up front for my enthusiasm about them. I am overjoyed with

the way the resin pieces came out and look forward to using them in my

current U-2S model. I'll try to keep the text objective here and let the

pictures of the pieces do the talking, but my enthusiasm will likely

bubble through.

I am only going to show the peices as they come out of the set in this

review. Expect to see a built-up U-2S in the coming months on HyperScale

using all these sets.

This review is on the Fuselage Update Set (CEC48442).

An Update Set Is Born

This set started simply as me wanting to make a better looking version

of the main wheel well. What Italeri provides in the kit is not

even close to what it should look like. They provide a shallow box that is

not even deep enough to hold the wheels. My first attempt to fix this

(working blind with no real documentation) was nothing more than deepening

the forward section and adding some wiring.

Kit Main Wheel Well |

Re-Built Main Wheel Well |

Then, I received a set of pictures from Dave Roof that included a few

main wheel bay shots. Now I had more information on the area than I really

wanted to know. After some long study of the pictures and more than a

little soul searching, I decided to take the plunge and attempt to

scratch-build a new main wheel bay. The scratch-built wheel bay would not

use any of the already modified kit main wheel well, so if I failed in my

attempt to make a correct wheel bay, I could always fall back on the usage

of the modified kit part.

Without getting into a lot of description, I took sheet styrene (mostly

0.030" thickness) and started cutting pieces and assembling them to match

what I was seeing in the pictures. I cut two pieces to be the bulkheads at

the front and rear of the bay. I cut, bent, and assembled pieces to create

the "V" formed by the inner sides of the ducting. I cut a series of

styrene circles and cut them into quarters, then attached them to the

sides of the "V" to act as formers for the rounded outer sides of the

ducting (step 1, below). With this built up, I then skinned the ducting in

0.005" sheet styrene (step 2, below).

The scratch-built unit (up to this point) created the basic shapes of

the wheel bay. After some more dry-fitting of the new unit to verify that

it still fit in the fuselage, I started adding the minor details like

structural ribbing, actuators, and nitrogen bottles (step 3, below). I

added mounting points on the rear wall for the landing gear strut and

built-up the center position where the strut's retraction arm attaches. I

was starting to get rather excited at the look of the new main wheel bay.

Step 1: Basic Shapes |

Step 2: Skinned Ducting |

Step 3: Details Added |

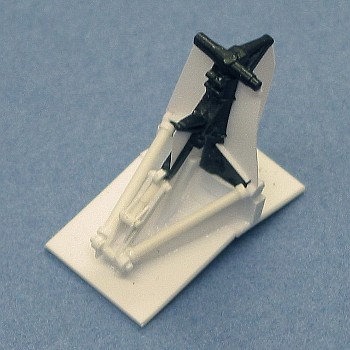

With this killer wheel bay shaping up, now the kit landing gear strut

just looked bad. I had already cut down the two mounting pivots so the

piece could be added after the fuselage was assembled. I knew I wanted to

add the reinforcing braces, but I was originally thinking that I would not

do anything else to the gear strut. Closer study of Dave Roof's pictures

showed that I could improve the gear strut and, specifically, the

retraction linkage. I set off making a better retraction linkage using

assorted sizes of Evergreen strip and rod stock. I also used

several disks punched out with my Wadron punch set. The results are

shown below.

Wheel Bay Forward Bulkhead |

Main Landing Gear Strut: Kit and Re-built |

All along this time I was e-mailing with "Mike B" in Canada. He

commented that I really needed to make these pieces available to someone

to be cast up into a resin update set. This made sense. I wanted to build

at least two U-2R/S models and I sure did not want to do this scratch

building a second time. Since I had worked with Meteor Productions before,

they were the natural choice for me to talk to on this topic. Obviously,

they were interested.

I made a series of modifications to the wheel bay to make it more

cast-able. Most of this related to making the intake ducting into separate

add-on pieces. I also added a bunch of 0.005" sheet styrene relief cuts so

that the main landing gear strut could be cast as a one-piece molding.

Main Wheel Bay, Modified for Casting |

Main Landing Gear Strut, Modified for Casting |

The Update Set Described

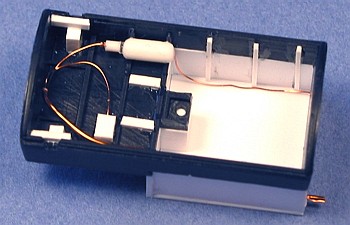

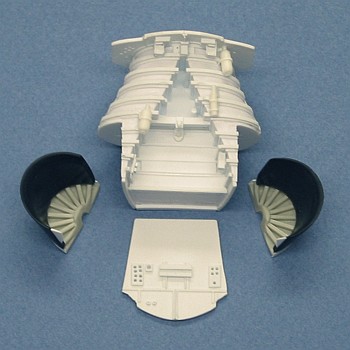

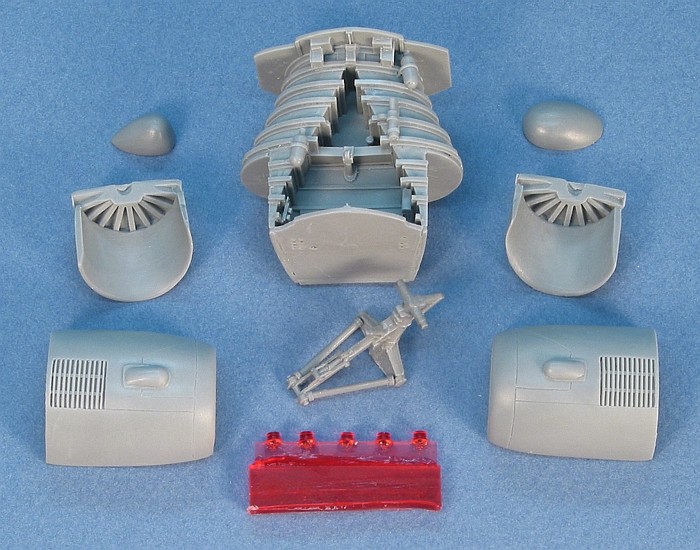

The set is made up of 13 pieces. Most are molded in the medium gray

resin that we have come to expect from Cutting Edge. There is also

a small sprue of clear red resin for the anti-collision lights. There were

no molding imperfections in the test pieces sent to me.

The Full Update Set |

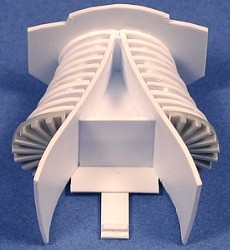

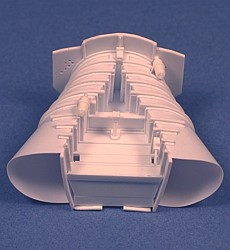

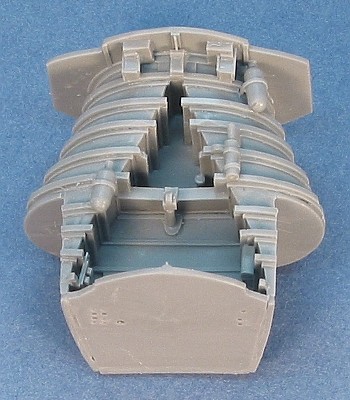

The centerpiece of this set is the full main wheel bay. I am very

impressed at the casting process and how well it captured all the detail

that I had in the original master piece. Casting does have limits on what

it can do, though. Most of the wiring in the wheel bay stands well away

for the inner surfaces. To simplify things, and because I did not want to

incorrectly represent the wiring just for casting purposes, I chose to

leave the wiring off the master piece. It will not be difficult to add to

the casting. Pictures in the instruction sheet provide instruction on

where the wiring is found. Flashed over holes in the front and rear

bulkheads provide location information on the wiring.

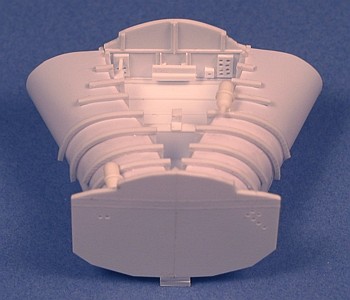

Main Wheel Bay, Looking Rearward |

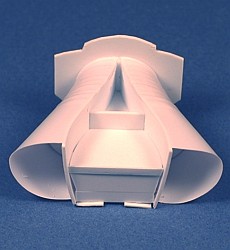

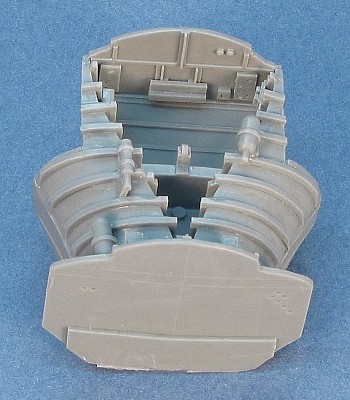

Main Wheel Bay, Looking Foreward |

The intake ducting attaches to the sides of the wheel bay as seen

below. The main landing gear strut is a one-piece casting. Fearing the

structural weaknesses that a multi-piece strut would have introduced, I

made a point of trying to get the main landing gear strut to be a single

piece. It means there are some excess mold marks and flash to remove from

the piece, but the strength of a one-piece strut is worth this little

headache.

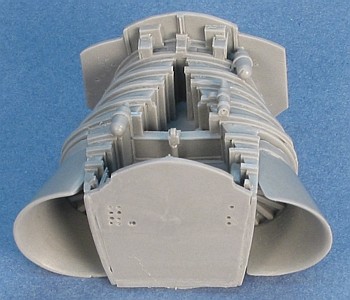

Main Wheel Bay, Ducts Attached |

Main Landing Gear Strut |

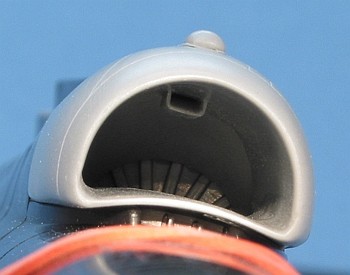

Extending the ducting forward, the set provides replacement intake

pieces. These are one-piece seamless intakes that directly replace the kit

intake pieces. The ECM blisters found on all the later aircraft are molded

in place on the intake sides. I felt it was easier ot file the ECM dimples

off than it would be to have to add them. Hence, if the aircraft being

modeled does not need the ECM dimples, remove them.

Forward Intake Pieces |

View Back the Assembled Intake |

Beyond the wheel bay and engine intakes, the set also provides a few

items missing from the Italeri kit to update it to more current

configurations. Both the forward and rear data link antenna bulges are

provided. The two bulges reflect the shapes of the later style data link

fairing found on current U-2S aircraft. Also, the PLSS cooling intake

scoop found on the left fuselage side is provided.

Data Link Bulges |

PLSS Cooling Scoop |

Anti-Collision Lights |

The final items in the set are clear red castings of the anti-collision

lights. The set provides three lights. On early airframes (before the

introduction of Senior Span/Spur), only two lights were on the aircraft.

When the airframe is updated to support Senior Span/Spur, the upper light

is deleted and replaced by two lights moved further back the spine and

separated by about eighteen inches.

I wrote this review to show a little of what goes into the making of a

set of masters for a resin kit update. And, of course, I wrote this to

show off the new set. The castings caught every detail of my original

masters with great clarity. As the designer of the masters, I do not think

it is my place to recommend this set or not. I will let the pictures in

this posting speak for themselves and leave any recommendations to a more

objective reviewer.

As many people have noted, the list of statistics at the end of each of

my project postings makes me a true "bean counter". This posting would not

be complete without listing my time spent on the project. For the record,

on all three U-2R/S update sets collectively, I spent 86.2 hours (5.9 on

research, 80.3 on contruction). Very few models in my built collection

have reached this high a number of working hours. Wanting to build more

than just one U-2R/S (eventually), the time spent here will save me time

in having to scratch-build all these items for each U-2 model that I

build.

(Newest to Oldest)

-

U-2R/S Walk Around by David W Aungst

On-Line

HyperScale Reference, 2003

-

U-2: The Second Generation by Chris

Pocock

World Airpower Journal, Volume 28, AirTime Publishing, 1997

-

Dragon Lady by Ted Carlson /

Toyokazu Matsuzaki

Koku-Fan Magazine, Volume 1996-04, Bunrin-Do Company, Limited, 1996

-

Recce Tech by Paul F Crickmore

Osprey Color Series, Osprey Aerospace Publishing, 1989

-

U-2 Spyplane in Action by Larry

Davis

, Squadron In Action #86, Squadron Publishing, 1988/2002

-

Lockheed U-2R/TR-1 by Jay Miller

AeroFax MiniGraph #28, AeroFax, Inc., 1988

-

Lockheed U-2 by Jay Miller

AeroFax AeroGraph #3, AeroFax, Inc., 1983

Cutting Edge Modelworks products are

available online from Meteor Productions

website

Images and Information Copyright © 2003

David W. Aungst

This Page Created on 21 April, 2003

Last updated

14 August, 2003

Back to

HyperScale Main Page

Back to

Reviews Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search