|

F-8A/B/C/D/H/K/L

Airframe Conversion for

Hasegawa F-8E Crusader

Cutting Edge Modelworks

S u m m a r y

|

| Catalogue Number

and Description |

CEC48419 F-8A/B/C/D/H/K/L

Airframe Conversion for Hasegawa F-8E. |

| Scale: |

1/48 |

| Price: |

USD$16.99 |

| Contents and Media: |

Ten pieces in grey resin |

| Review Type: |

FirstLook (test-fitted) |

| Advantages: |

Very clean casting; excellent

detail; lots of alternate schemes available for other variants;

excellent fit; thoughtful engineering; supporting tabs on wing hump

replacement insert; accurate; execution of conversion not as

frightening as it first looks - quite straightforward |

| Disadvantages: |

Small upper fuselage lump in

front of wing must be backfilled and removed (but no big deal); no

locators on nose replacement halves so care is required in alignment. |

| Recommendation: |

Highly Recommended for anyone

wanting to depict an early F-8 |

Reviewed by Brett Green

HyperScale is proudly sponsored by Meteor

Productions

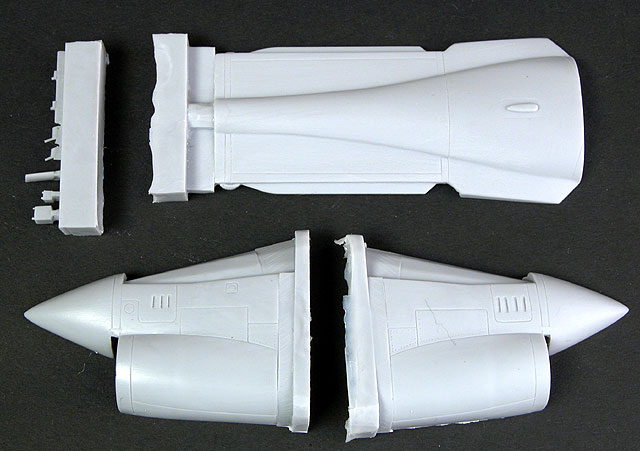

Cutting Edge's 1/48 scale F-8A/B/C/D/H/K/L Airframe

Conversion for Hasegawa F-8E comprises just ten parts in the familiar grey

resin.

This conversion addresses the smaller radar nose and

different vents/details; plus the "humpless" spine on these versions.

The parts are beautifully cast with no imperfections

on my review sample. However, as good as the parts looked, I wanted to see

how well they fitted.

At first glance this looks like a major conversion.

It does require the removal of the entire kit nose and the upper wing

halves to be sliced off the centre section. This prospect will be a little

frightening to many modellers, myself included!

However, I put my fears behind me, armed myself with

a razor saw and started preparing the conversion parts for assembly.

The Nose Section

Preparation and assembly of the replacement nose is

quite straightforward with a little time and care.

The join is along an engraved vertical line so

cutting the kit nose is a simple matter of following the panel. The resin

replacement parts must also be sawn off their casting block. Fortunately,

the resin is thin at the point of release and the separation line is

crisply engraved. Each of the four cuts took no more than 30 seconds.

Once the resin parts were free from their blocks,

some excess resin was removed from the instrument coaming. I found it was

easiest to slice this excess material off from inside the part

using a sharp hobby knife.

I also removed the single locating pin on the inside

of the nose cone, as it seemed to be more of an impediment than an

alignment aid.

Click the

thumbnails below to view larger images:

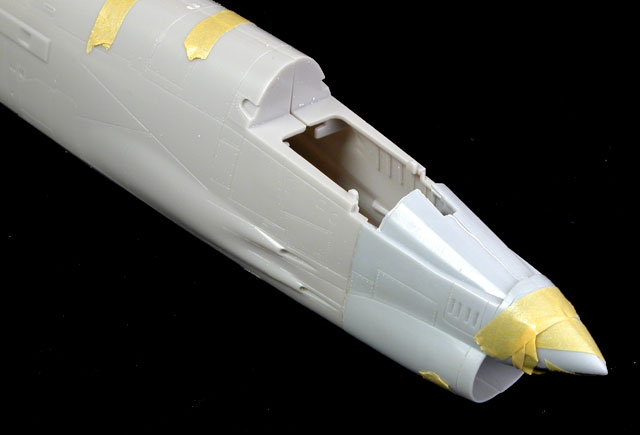

Do not join the resin nose halves yet!

It is absolutely essential for perfect alignment of

the resin nose and the kit parts that each nose half is glued to each

fuselage half before the fuselage is assembled.

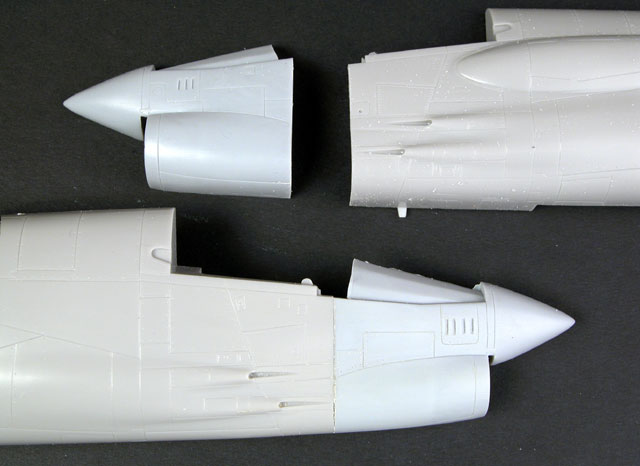

I found that the subtle contours of the kit fuselage and

the resin nose matched perfectly, but that some extra resin is cast on the

bottom edge (ie, the bottom is moulded with extra width). This has

presumably been done in favour of trimming rather than filling the bottom

fuselage join. What it means, though, is that the resin nose must be lined

up against the fuselage side, not the lower fuselage centreline.

Care is required when lining up the kit parts with the

resin nose. There are no locating tabs (there is not much room left inside

the fuselage once the intake and cockpit are installed), so the modeller

will be entirely responsible for avoiding ridges and poor alignment.

I found that the parts fitted extremely well. The resin

nose was secured with super glue, and the extra width was trimmed with a

sanding stick while regularly testing the width.

I next fitted the intake ducting parts to the fuselage to

confirm the width and check the fit of the fuselage halves. The ducting

was almost a snap fit and, although the fit of the fuselage halves was

tight, it looks very promising for a gap-free construction.

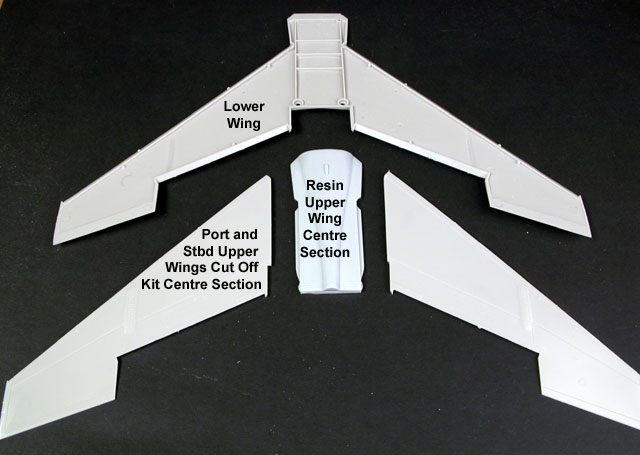

The Humpless Wing

Once again, the cuts take place along a panel line. This

time the panel line is raised.

I scribed along the appropriate panel line, then sliced

the front and back with a razor saw before snapping the wing halves off.

The resin replacement centre section was easily removed from its casting

block with a razor saw.

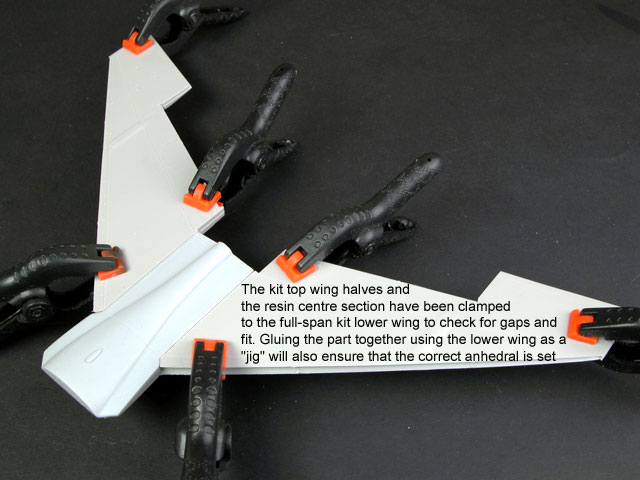

I decided to use the full-span lower wing as a assembly

jig for the upper wing. I laid the port upper wing on the locating

positions on the lower kit wing then added plastic clamps to hold the

parts in place. The long locating tab on the resin centre section was slid

under the clamped wing. Fit looked good. The starboard wing was then laid

on top of the other locating tab, confirming that the fit was gap-free on

the other side too.

This temporary assembly was then disassembled and super

glue was applied to the tabs. Both wing halves were attached to the centre

section while they rested on top of the lower wing, ensuring that the

correct dihedral was set.

A small hump remains on top of the fuselage in front of

the wing. This will need to be backfilled with putty or super glue, and

cut off the top of the fuselage.

Considering the interesting and colourful options afforded

by early Crusaders, Cutting Edge's 1/48 scale F-8A/B/C/D/H/K/L Airframe

Conversion is very welcome indeed.

Although some cutting of the donor kit is required, the

conversion parts are well engineered to help achieve perfect fit and an

authentic replica of an early F-8 Crusader in a surprisingly short time.

This conversion will be ideal for modellers with some

experience of working with resin parts.

Highly Recommended.

Thanks to Cutting Edge

Modelworks for the preview information

Cutting Edge Modelworks products, including

Cutting Edge Decals,

can be viewed at Meteor Productions

website

Review Text and Images Copyright © 2003 by

Brett Green

This Page Created on 03 March, 2003

Last updated

14 August, 2003

Back to

HyperScale Main Page

Back to

Reviews Page |

Home |

What's New |

Features |

Gallery |

Reviews |

Reference |

Forum |

Search